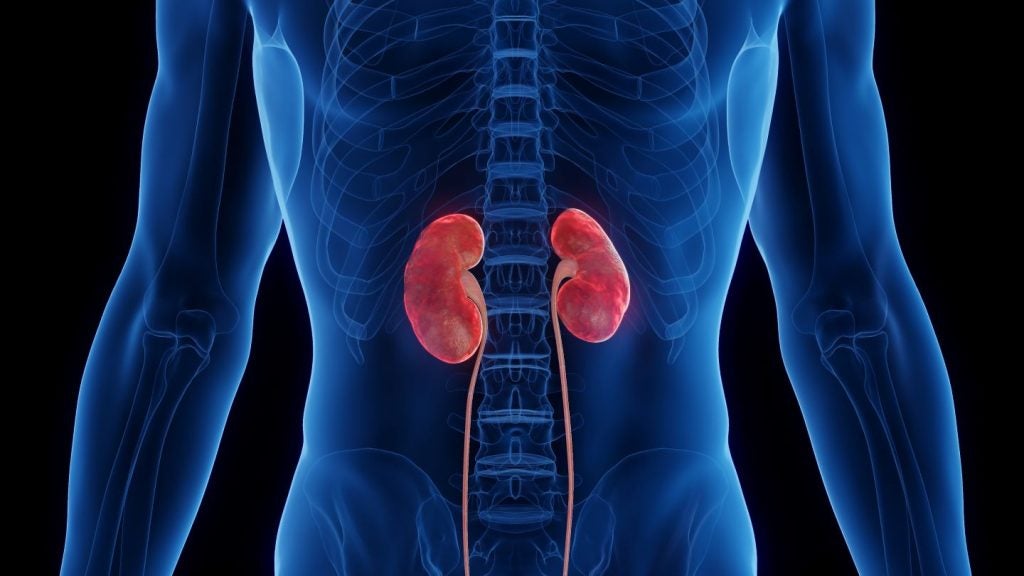

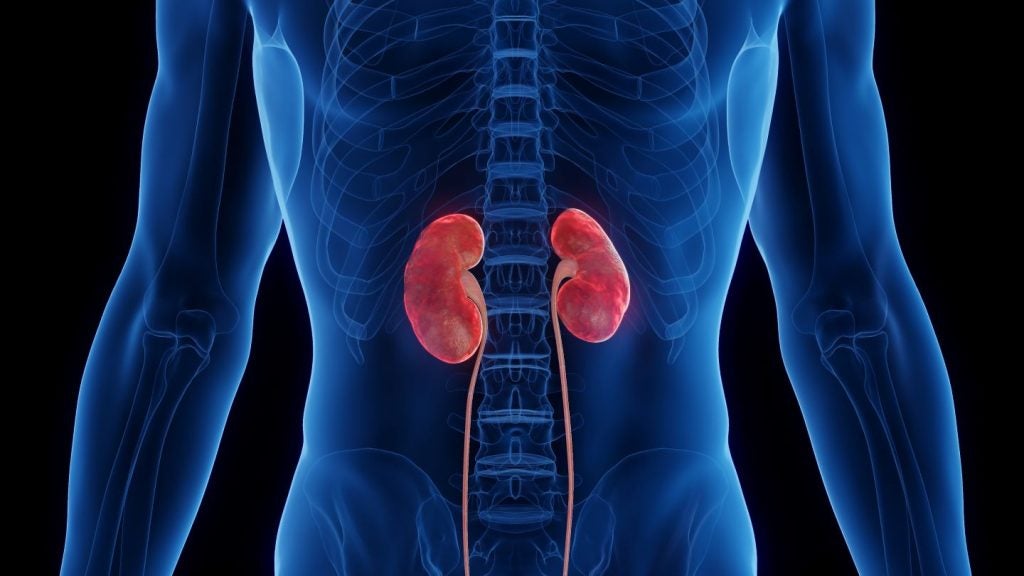

Artiva doses first subject in Phase I lupus nephritis treatment trial

The multi-centre, open-label trial aims to evaluate the safety and clinical activity of AlloNK along with monoclonal antibodies in LN patients.

The multi-centre, open-label trial aims to evaluate the safety and clinical activity of AlloNK along with monoclonal antibodies in LN patients.

The study will assess the economic and healthcare outcome benefits of Acarix's AI-powered CADScor System compared to traditional stress test.

The pharmaceutical industry continues to be a hotbed of patent innovation. Activity is driven by the evolution of new treatment...

Cleerly touts new data for AI cardiovascular software

Moderna’s Phase III Covid-19 vaccine trial meets primary endpoints

Gedeon Richter adopts TransPerfect’s trial management solutions

Artificial intelligence identified two evolutionary pathways of prostate cancer